Serious cyclists want to train year-round. Unfortunately, Missouri and Illinois don’t have year-round training climates.

The winter months often force cyclists indoors to use trainers, devices that attach to a bike to provide resistance while the bike remains stationary. While the trainers keep riders spinning on familiar equipment, they lack a key element: motion.

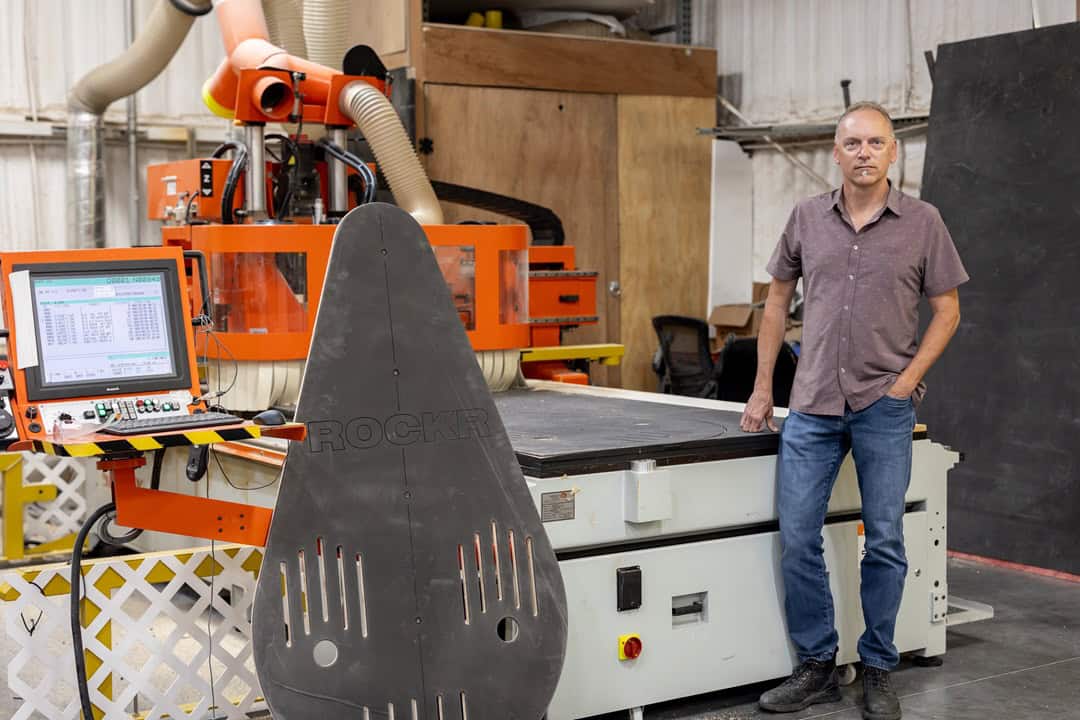

“Because trainers hold the bike rigid, the bike can’t move, but your body still does,” explains Chip Self, a cyclist, entrepreneur, and owner of SBR Bikes & Brews in Chesterfield, Missouri. “The result is a less natural ride and pain in your butt, back, shoulders, wrists, and knees.”

To address this issue, cyclists have worked on solutions for years. Around 2015, Self found a Facebook community of riders building their own “rocker plates.” For the most part, the DIY enthusiasts’ plates consisted of two pieces of plywood with tennis balls or hinges between them. A cyclist attaches their trainer to the top platform and — voilà — there’s motion for the bike and rider.

After meeting with another local cyclist, Mike Bobelak, and seeing the rocker plates he had made, a lightbulb turned on for Self.

“I saw that this was a potential solution for the problem with indoor trainers,” Self recalls.

Inspired, Self constructed his own model, which he dubbed the Rockr. The first time he tried it, the ride was so comfortable that he trained for three hours — two hours longer than his usual.

The Rockr Axis at work. (Rockr)

It wasn’t perfect, but Self had the equipment and materials to refine it. One of his businesses, St. Louis Case Company, manufactures gear cases for musicians. So, at his Valley Park manufacturing plant, he used his high-end cutting equipment, plentiful raw materials, and connections with other manufacturers to improve the Rockr and eventually bring it to market.

Self’s bike trainers incorporated numerous innovations, including:

- Suspension balls. Self utilized 7-inch playground balls to improve the left-right and fore-aft (front-back) motion.

- Streamlined shape. Instead of a square piece of wood, Self cut his birch ply into roughly the shape of a bicycle seat. This allowed him to cut more platforms from a single piece of wood, reducing waste by 80 percent and lowering costs.

- Slip-free surface. When Self heard of riders sliding around on their platforms, he laminated a piece of foam rubber material securely to the surface to reduce slippage.

“Once I felt I’d made significant contributions to my existing ideas, I applied for a patent to cover the innovations, and that unit is what we sell now as the Rockr Pro,” says Self. “The Rockr Pro has not changed substantially in the nine years since we released it.”

In addition to the Pro, Rockr now offers the Pod Lite, which replicates the Pro’s motion but with no moving parts. It sits on rocker fins, like a rocking chair.

“Many people insist it’s their favorite Rockr because it’s so simple,” Self notes.

Rockr’s latest model, the Axis, uses a higher virtual pivot axis to create a more natural ride. It also preserves the rider’s power and adds up to six inches of fore-aft motion. Talking to Self, you can sense his immense pride in his company’s newest release.

“It’s the closest anyone has been able to get to the movement and feel of riding in real life,” Self says. “And it’s made right here in Missouri.”

For more information, go here.

Author: Tim Fox is a contributor to Terrain.

Top image: Chip Self at his Rockr shop. (Courtesy of Rockr)

Leave A Comment